Products

-

GaoLin Decorative Panels

The decorative panels utilize high-quality density boards, particle boards, and plywood from the GaoLin brand, ensuring excellent performance in maintaining panel flatness, structural stability, and resistance to deformation.

-

Structural Plywood-Plywood

High-quality veneer is selected as raw material, the board is sawn straight, with flat surface, strong structural stability。The plywood boasts a high modulus of elasticity and static bending strength. DYNEA phenolic resin is used as an adhesive, providing water and moisture resistance, making it suitable for outdoor environments.

-

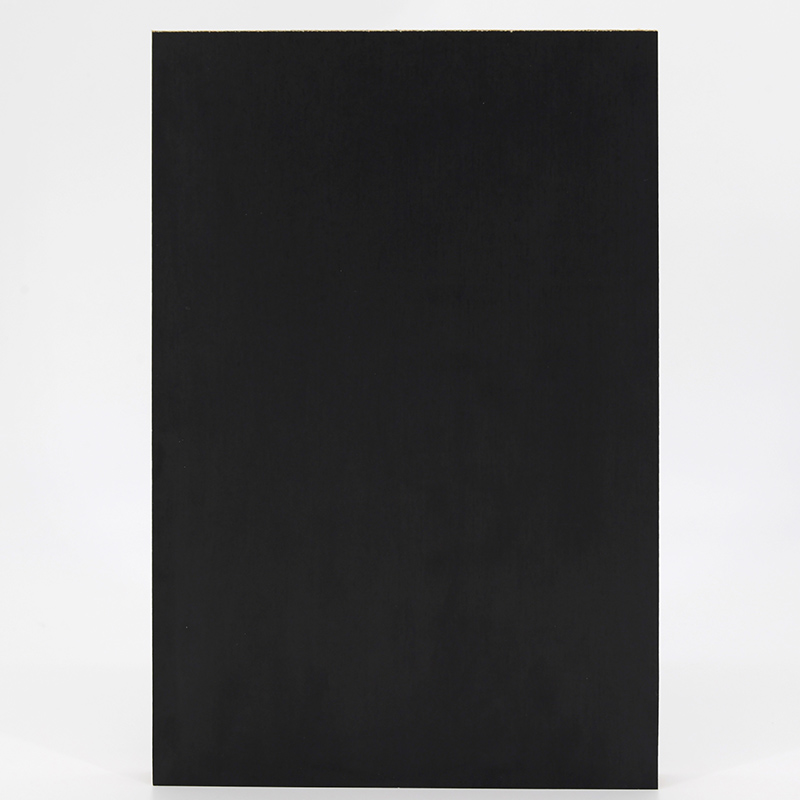

Black Film faced plywood-Plywood

High-quality veneer is selected as raw material, the board is sawn straight, with flat surface, strong structural stability, adopting Finnish DYNEA phenolic glue+Finnish DYNEA Phenolic coated paper. high gluing strength and small deformation.Strength range up to F4-F22,Waterproof and moisture-proof.

-

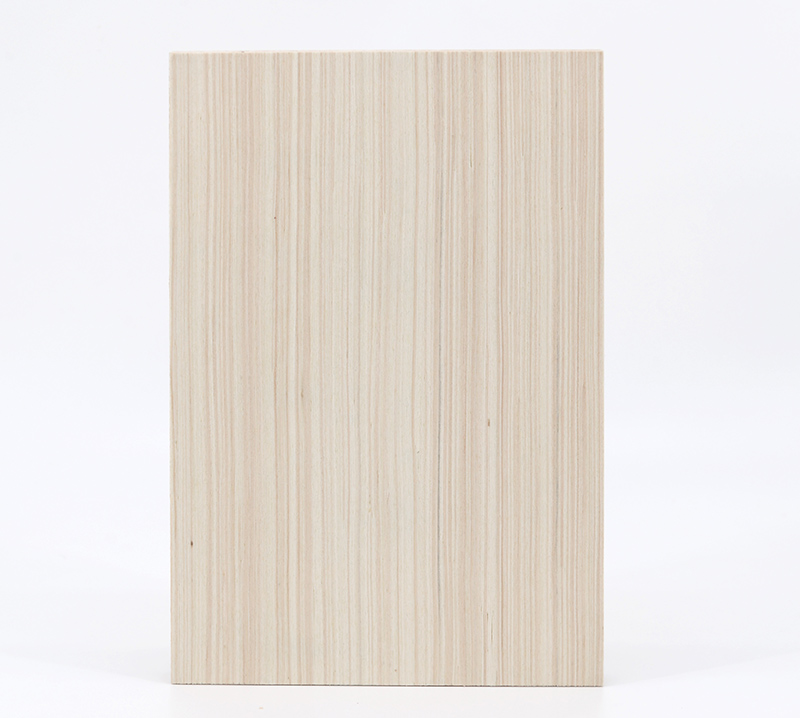

Melamine Board Substrate-Plywood

High-quality veneer is selected as raw material, the board is sawn straight, with flat surface, strong structural stability, high gluing strength and small deformation.

-

Ordinary furniture use board-Plywood

High-quality veneer is selected as raw material, the board is sawn straight, with flat surface, strong structural stability, high gluing strength and small deformation

-

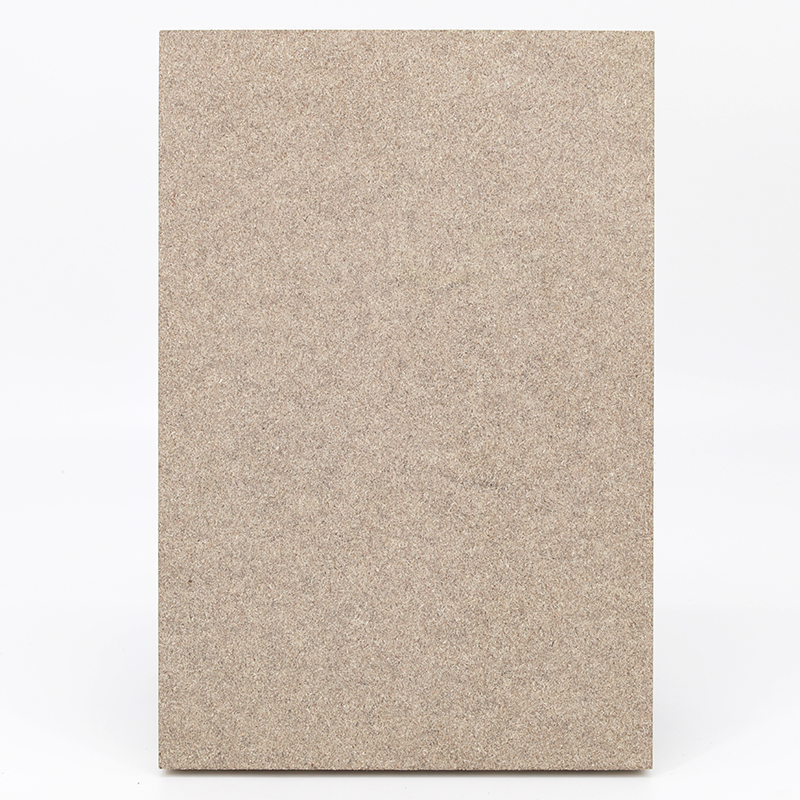

Furniture Board -Particleboard

When used in dry state, furniture particleboard has uniform structure and good processing performance. It can be processed into large-format board according to demand, and has good sound-absorbing and sound-isolating performance. It is mainly used in furniture manufacturing and interior decoration.

-

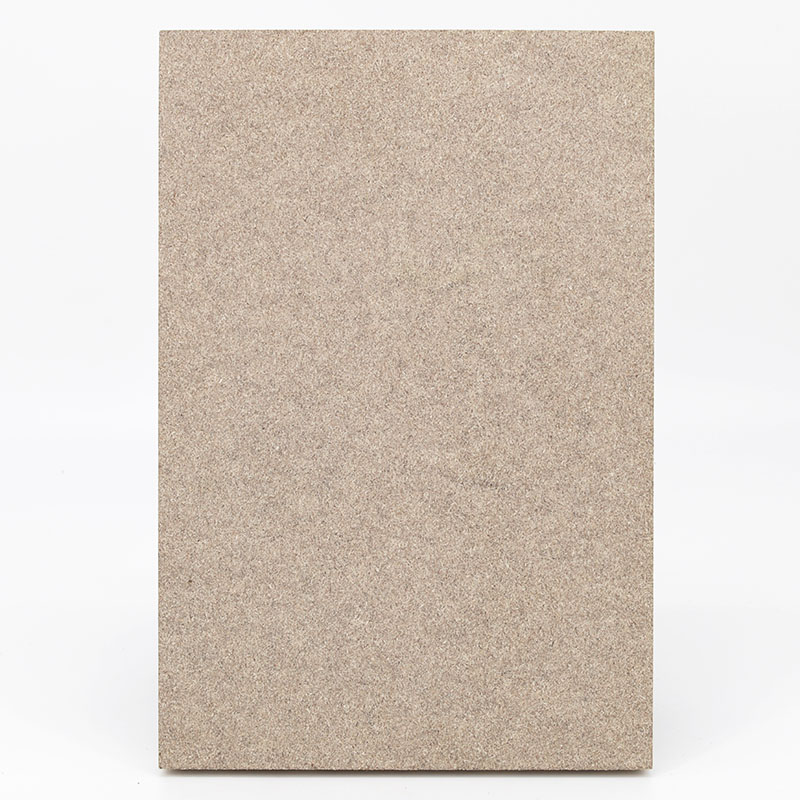

Moisture-Proof Furniture Board-Particleboard

Particle board is used in the humid state, with good moisture-proof performance, not easy to deformation, not easy to mold and other characteristics, 24 hours water absorption thickness expansion rate ≤8%, mainly used in bathroom, kitchen and other indoor products with high moisture-proof performance requirements for processing base material.

-

UV-PET cabinet door board-Particleboard

UV-PET board particleboard

Using furniture particleboard in the dry state, the product structure is uniform, the size is stable, can be processed long board, small deformation. Mainly used for cabinet doors, wardrobe doors and other door plate processing base material. -

Backup Board For Printed Circuit Board Drilling-Fiberboard

Professional to meet the requirements of the use of electronic circuit processing plate,It has the advantages of high hardness, flat surface without deformation, small thickness tolerance and good machining performance

-

Carve And Mill Fiberboard-Fiberboard

It has the advantages of high surface finish, fine fiber, grooving type grinding without fuzziness and good waterproof performance.Suitable for deep engraving, engraving, hollow out and other processing methods.Often used for cabinet doors, crafts and other products with higher quality requirements.

-

Furniture Painted Board-Fiberboard

It is suitable for the substrate board used for direct painting processing. It has the advantages of flat surface, smooth surface, small dimensional tolerance, less paint absorption and saving paint consumption.It is suitable for the products with high requirements on the finish, and it is not suitable for hot pressing.

-

Ordinary Furniture Use Board-Fiberboard

Formaldehyde emission reaches ENF, formaldehyde emission measured by climate box method is less than 0.025mg/m³, 0.025mg/m³ lower than E0 grade, and the water resistance of the product is better than E0 grade and E1 grade products of the same specification.

Suitable for furniture manufacturing, pressure paste, spray painting, shallow carving and engraving (less than 1/3 board thickness), sticker, veneer, blister processing and other purposes. It has the advantages of smooth surface, reasonable structure, easy deformation, small dimensional tolerance, uniform density structure and superior performance.